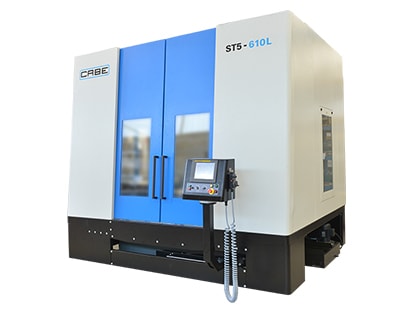

SLOTTING MACHINES

A rich and varied range of products that meets the needs of clients from all over the world. From the manual vertical slotting machines to the most innovative electronic control solutions with up to 5 axes.

The machines are unique because of the construction in cast iron fusion that ensures cutting precision and no vibrations, normally the weak point of the machines built in welded steel.

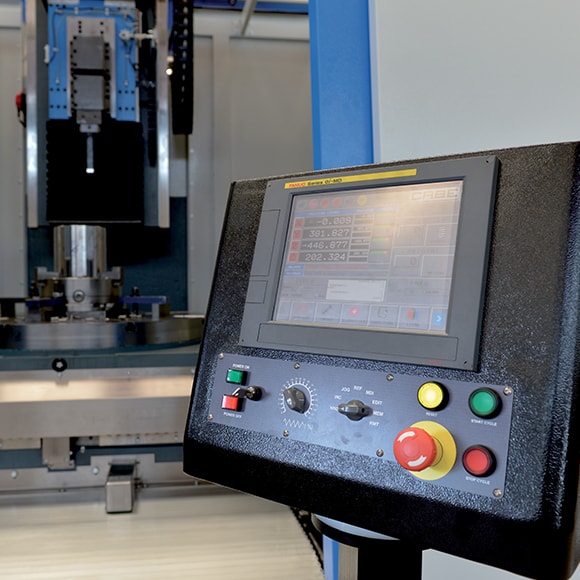

To improve the quality and the performance of the machines, studies and projects, Cabe are continually looking for innovative solutions and materials. The programming of the slotting machines and the user interface have reached maximum levels in the recent ST CNC with up to 5 controlled axes: the set-up of the machines is

LINE OF SLOTTING MACHINES

From the manual vertical slotting machines to the most innovative electronic control solutions with up to 5 axes. The CNC machines are divided into 2 lines:

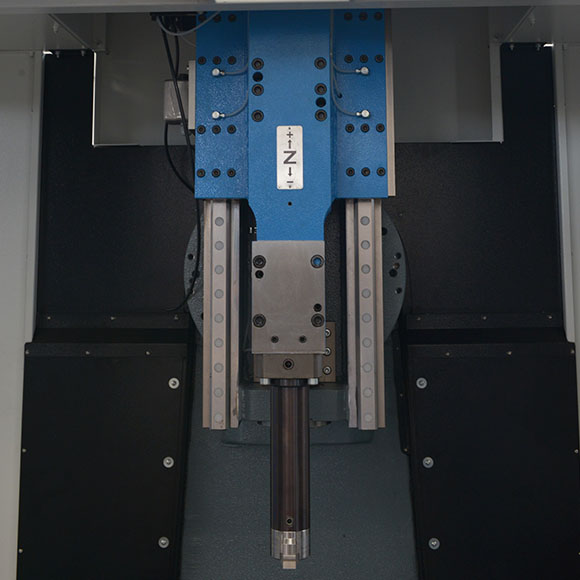

ST CNC from 2 – 5 controlled axes and with the axis moving the head controlled by brushless motors, TTF CNC from 1 – 3 controlled axes with the traditional rod-crank system for the movement of the head.

INSTALLED MACHINES

The adjustable ramholder makes it possible to have a steady cut in each height. The free programmable controller will let you cut each shape and control the movement of the machine.

We were looking for a slotting machine where we could produce long details as well as being flexible and found CABE.

The technology developed and proposed by the machine inspired us with confidence. We are fully satisfied with the features we expected.

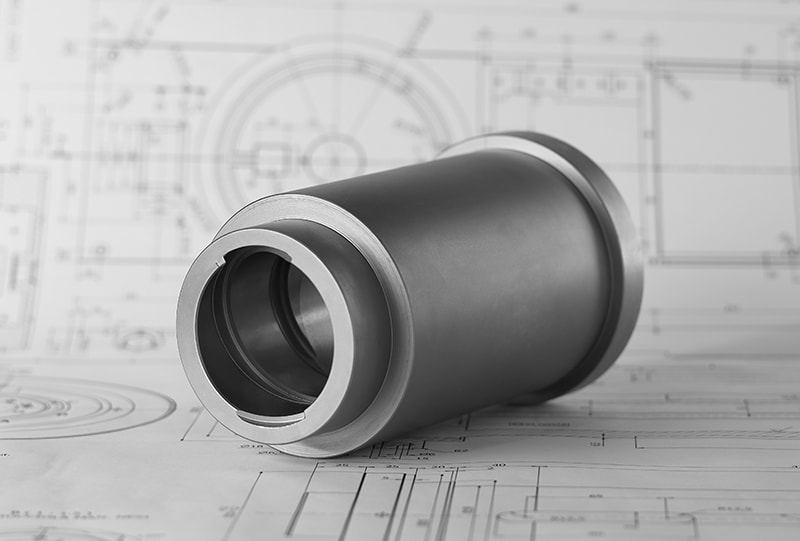

CABE TOOLS

Each Cabe machine is characterized by a wide range of accessories, including hand tools for slotting machines studied by Cabe and fixing and replacement systems on their machines.

The technical team studies the types of processes necessary for the client and provides the most suitable custom tools for the material or the cutting speed required.

The new line of tools for the slotting machine is characterized by an advanced internal refrigerant cooling system that helps the chip leakage during machining.

PROCESSING TYPES

HIGHLIGHTS

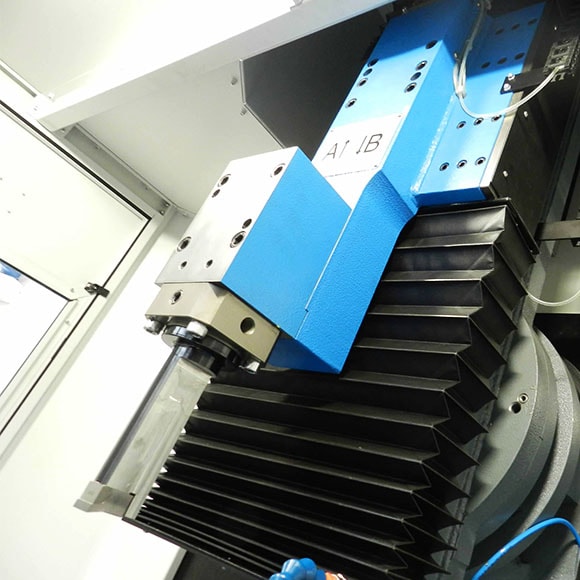

CUTTING AXIS

The axes controlled by brushless motors guarantee quick set-up of the machine, constant cutting rate thanks to the elimination of the traditional rod-crank system for the movement of the head, processes so far impossible to realize. Thanks to the interpolation of the axes, it is not necessary to incline the head to realize conical slots.