Slotting Machine

ST5 CNC

New design, cutting-edge technology. The newest Cabe model promises the implementation of ground-breaking articulated machining.

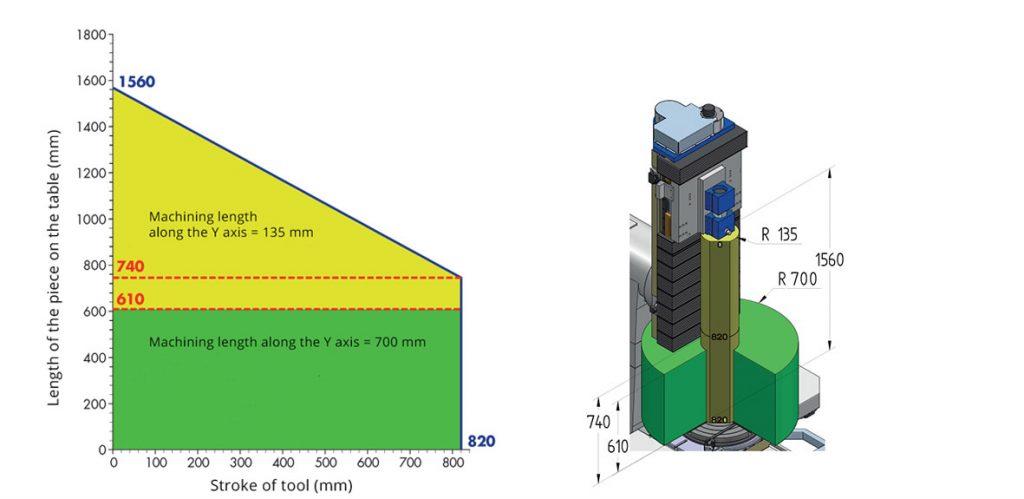

The fifth axis, introduced expressly for the models with elevated stroke of the tools, consents to easily modify the distance between the table and the underhead allowing a fast change of the machining.

With great simplicity in its design, also supported by a constant cutting speed, it allows the execution of complex figures, which until now has not been possible using traditional models. The machine is ideal for the machining of particular big pieces.

Slotting Machine

ST5 CNC

New design, cutting-edge technology. The newest Cabe model promises the implementation of ground-breaking articulated machining.

The fifth axis, introduced expressly for the models with elevated stroke of the tools, consents to easily modify the distance between the table and the underhead allowing a fast change of the machining.

With great simplicity in its design, also supported by a constant cutting speed, it allows the execution of complex figures, which until now has not been possible using traditional models. The machine is ideal for the machining of particular big pieces.

Vanguard Technology

The adjustable ramholder makes it possible to have a steady cut in each height. The free programmable controller will let you cut each shape and control movement of the machine.

Performance & Flexible

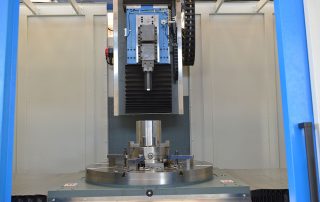

Designed to be particularly flexible and performing, the ST5 CNC is equipped with Fanuc control and motors. All of the processing elements (tools, origins, cycles composed of queued processing) are saved in organized libraries inside the control and guarantee quick machine set-up.

The movement of the head, controlled by Fanuc brushless motors, is done with the control, that keeps in memory the start position and repeats it automatically if needed.

Highlights

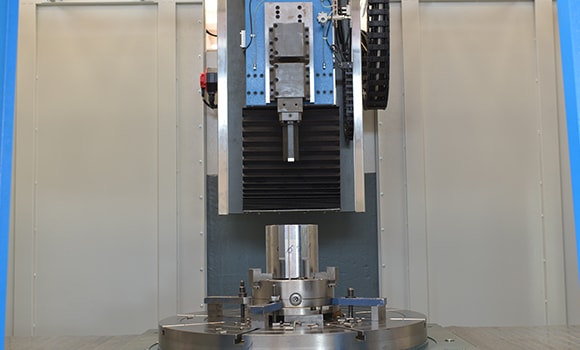

Tool Holder Block

The innovtive tool holder with high repeatability guarantees that the tools are always at the centre of the hole.

Combined with the tool holder, the “VCT” system, virtual tool change, that allows two processes with different tools without having to stop the machine to make the change.

Controlled cutting axis

Five axes controlled by brushless motors ensure quick set-up of the machine, constant cutting rate thanks to the elimination of the traditional rod-crank system for the movement of the head and processes so far impossibile to obtain.

Thanks to the interpolation of the axes, it is not necessary to incline the head to realize conical slots.

Technical Characteristics

- FANUC control, 0i-MF touch screen 10.4” model.

- Controlled swivel pieceholder table (C axis).

- Automatic disconnection of the tool during ascent phase.

- Net oil cooling system.

- The controlled axes are driven by brushless FANUC motors.

- The controlled axes are managed directly by the controller and the movement in manual mode is guaranteed by a remote handwheel.

- Direct reading of the position on all linear axes.

- The linear axes slide on recirculating roller guides to ensure dynamicity and precision of the movements, preloaded with centralized forced lubrication.

- The command screws for X and Y axes are ball recirculation type, rectified and preloaded.

- The Z axis command screw is planetary roller type, due to the high loading torque.

- The 5th axis, Z1, in the model 610 allows the regulation of the ram thanks to the brushless motor. This system helps to reduce or increase the distance between the underhead and the swivel table according to the slot to be realized.

- Practical and removable chip collection tank, located below the table.

- Safety around the illuminated work area is guaranteed by practical guards (2 doors) that at the same time facilitate the positioning of the pieces and prevent accidents.

- Service keys and user manual supplied.

- ”V” universal tool holder block.

- Tower signalling machine status.

- ”Fine” adjustment of the tilting head with handwheel.

- Pneumatic air blow kit for cleaning blind holes.

- Automatic chip conveyor: if present, the maximum workpiece length for machning is reduced.

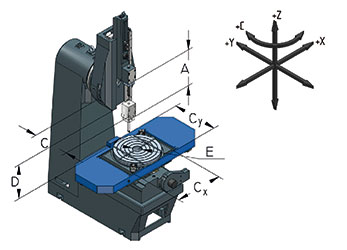

| Characteristics | Dimensions | ST5-610 |

|---|---|---|

|

Settable stroke of tool [mm]

|

A |

0-820 according to Ø piece

|

|

Distance between tool holder and column C 410 470 550 [mm]

|

C |

700

|

|

Distance underhead / Swivel table [mm]

|

D |

200-620 adjustable with 5th motor

|

|

Diameter of swivel table [mm]

|

Ø600

|

|

|

Centre table hole diameter [mm]

|

E |

Ø200

|

|

Strokes of the table [mm]

|

Cx x Cy

|

600×600

|

|

Motor / brake power [kW]

|

14

|

|

|

Adjustable work speed [mm/min.]

|

0-15.000

|

|

|

Maximum workpiece length for machining [mm]

|

Ø 190×1500

|

|

|

Electrical power

|

400V-50Hz-3fase

|

|

|

Approx. net weight [Kg]

|

12000

|

|

|

Machine dimensions LxWxH [mm]

|

4331x3326x3729

|