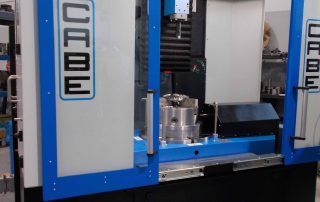

Slotting Machine

ST4 CNC

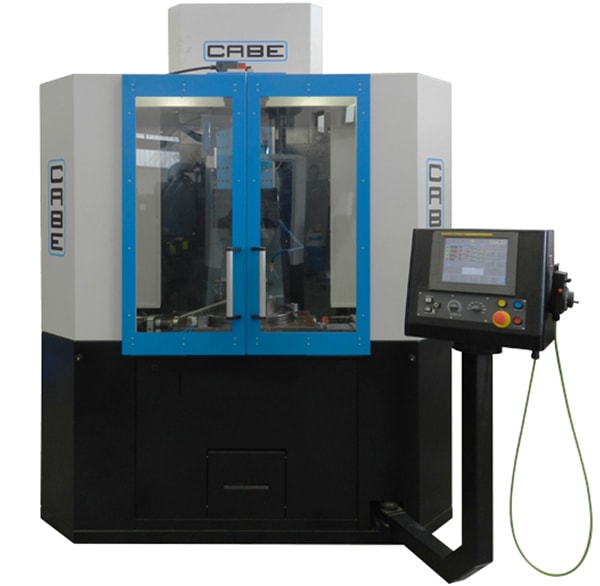

The slotting machine ST4 CNC allows the execution of complex figures, which until now has not been possible using traditional models.

Characterized by flexibility and great performance, the ST4 CNC slotting machine is the expression of the Cabe team’s continuous technological research.

The programming and the user interface have reached maximum levels: the set-up of the machine is very fast, the cutting speed is constant and complex processing is allowed.

Slotting Machine

ST4 CNC

The slotting machine ST4 CNC allows the execution of complex figures, which until now has not been possible using traditional models.

Characterized by flexibility and great performance, the ST4 CNC slotting machine is the expression of the Cabe team’s continuous technological research.

The programming and the user interface have reached maximum levels: the set-up of the machine is very fast, the cutting speed is constant and complex processing is allowed.

Vanguard Technology

We were looking for a slotting machine where we could produce long details as well as being flexible and found CABE.

Breakthrough Results

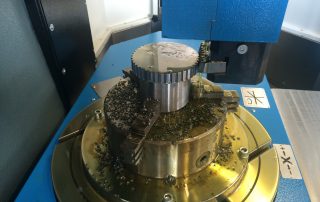

With the slotting ST4 and ST5 it is possible to perform machining processes previously impossible to achieve.

The traditional rod-crank system for moving the tool has been replaced by a servo-controlled linear axis which guarantees a constant cutting speed, optimizing tool life.

The software includes functionalities to realize decreasing progress, and chamfering of the corners, tangential slots. A breakthrough technology to achieve superior performances and new and unique processing.

Innovative Processing

BLIND SLOTS

Blind slots without discharge hole and discharge inclinations of up to 45°

CONICAL SLOTS

Conical slots obtained with the interpolation of 2 axes (Z and X or Y).

HELICAL SLOTS

Helical slots obtained with the interpolation of 2 axes (Z and C).

MAAG CUTTING

It is possible to realize maag cutting method.

Technical Characteristics

- FANUC control, 0i-MF touch screen 10.4” model.

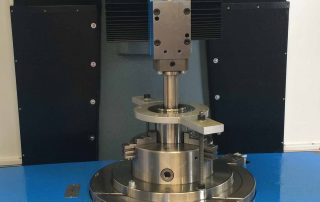

- Controlled swivel pieceholder table (C axis).

- Automatic disconnection of the tool during ascent phase.

- Net oil cooling system.

- The controlled axes are driven by brushless FANUC motors

- The controlled axes are managed directly by the controller and the movement in manual mode is guaranteed by a remote handwheel.

- Direct reading of the position on all linear axes.

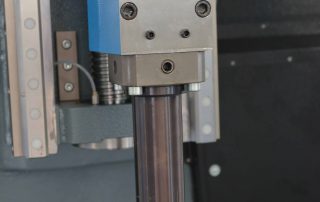

- The linear axes slide on recirculating roller guides to ensure dynamicity and precision of the movements, preloaded with centralized forced lubrication.

- The command screws for X and Y axes are ball recirculation type, rectified and preloaded.

- The Z axis command screw is ball recirculation type.

- Practical and removable chip collection tank, located below the table.

- Safety around the illuminated work area is guaranteed by practical guards (2 doors) that at the same time facilitate the positioning of the pieces and prevent accidents.

- Service keys and user manual supplied.

- ”V” universal tool holder block.

- Tower signalling machine status.

- ”Fine” adjustment of the tilting head with handwheel.

- Pneumatic air blow kit for cleaning blind holes.

- Automatic chip conveyor: if present, the maximum workpiece length for machning is reduced.

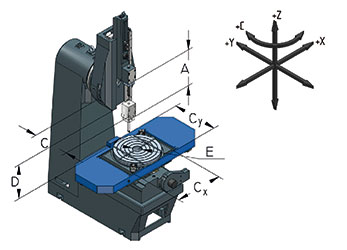

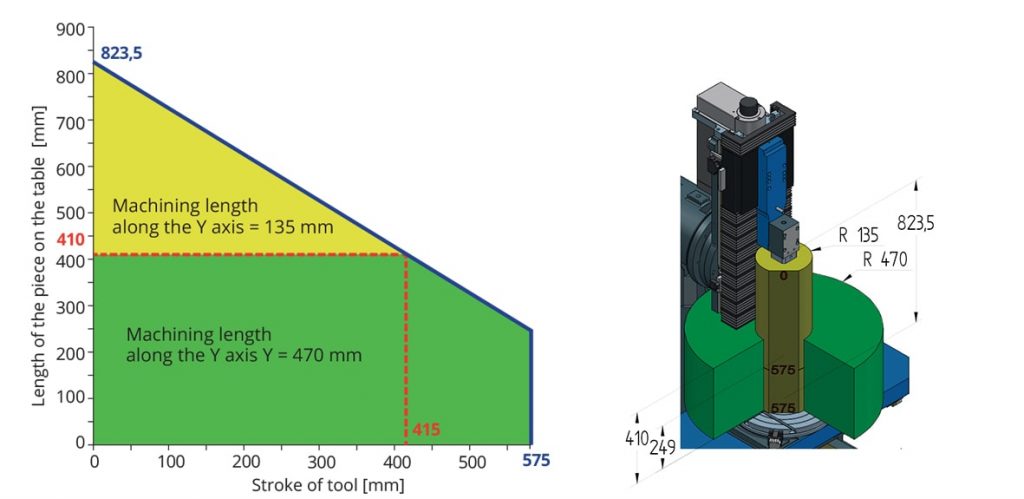

| CHARACTERISTICS | DIMENSIONS | ST4-410 |

|---|---|---|

|

Settable stroke of tool [mm]

|

A |

0-575 according to Ø piece

|

|

Distance between tool holder and column [mm]

|

C |

470

|

|

Distance underhead / swivel table [mm]

|

D |

420

|

|

Diameter of swivel table [mm]

|

Ø500

|

|

|

Centre table hole diameter [mm]

|

E |

Ø100

|

|

Strokes of the table [mm]

|

Cx x Cy

|

410×320

|

|

Motor / brake power [kW]

|

6,5

|

|

|

Adjustable work speed [mm/min.]

|

0-15.000

|

|

|

Maximum workpiece length for machining [mm]

|

Ø95×1200

|

|

|

Electrical power

|

400V-50Hz-3phase

|

|

|

Approx. net weight [Kg]

|

2400

|

|

|

Machine dimensions LxWxH [mm]

|

2000x2050x2620

|