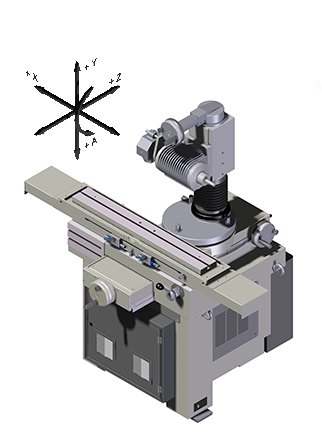

Manual Grinding Machine

SIMPLE 500

The range of universal grinding machines stand out for their reliability and great stability.

They are characterized by high quality components and a vast range of accessories, which make the machine adaptable to any grinding and tooling application.

The universal grinding machine can be used for grinding normal tools (mills, tips, taps, boring tools, countersink tools, lathe tools) or for small grinding applications (max 400 mm stroke) both on flat surfaces (tangential) and on round surfaces (hole ID / OD).

GRINDING MACHINE

SIMPLE 500

The range of universal grinding machines stand out for their reliability and great stability.

They are characterized by high quality components and a vast range of accessories, which make the machine adaptable to any grinding and tooling application.

The universal grinding machine can be used for grinding normal tools (mills, tips, taps, boring tools, countersink tools, lathe tools) or for small grinding applications (max 400 mm stroke) both on flat surfaces (tangential) and on round surfaces (hole ID / OD).

Highlights

Technical Characteristics

- Particular body base made to gather lubrorefrigerant liquid.

- Rolling friction rail on worktable and support head carriage.

- Electric spindle driving with three-phase inverter, dynamic range (2000/7000Rpm).

- Double locking for wheel center.

- Predisposition power supply for optional accessories.

- Ergonomic design.

- Versatile.

- Reduced maintenance.

- Orientable champing head with disc and notches.

- Fixed and elastic tailstock with sliding sleeve.

- Pen-holder.

- Portable spindles.

- Diamond-holder.

- Centre measuring device.

- Service keys.

- Combitek.

| CHARACTERISTICS | |

|---|---|

|

Longitudinal axis – piece-holder table

|

|

|

Longitudinal useful stroke [mm]

|

500 |

|

Piece-holder table length[mm]

|

970 |

|

Piece-holder table width [mm]

|

120 |

|

Piece-holder table inclination on horizontal plane, micro-metric

|

±45°, ±12°

|

|

Transverse axis – head-carriage

|

|

|

Transverse useful stroke [mm]

|

270 |

| Vertical axis – wheel centre head | |

|

Vertical useful stroke [mm]

|

230 |

|

Vertical stroke of wheel centre spindle on sliding head [mm]

|

140 |

|

Overall useful stroke [mm]

|

370 |

|

Planetary base orientation on horizontal plane, radius [mm]

|

±180°, 90 mm |

|

Wheel centre head orientation on horizontal plane

|

±180° |

|

Wheel centre electrical spindle

|

|

|

Orientation on vertical plane

|

±180° |

|

Speed of rotation in both directions

|

2000Rpm/7000Rpm

|

|

Motor power

|

1,5kW-2000Rpm/2.6kW-7000Rpm |

|

Maximum diameter of installable grinders

|

150mm-2000Rpm/100mm-7000Rpm |

|

Standard accessories

|

|

|

Tool attaching clamping head [mm]

|

ISO 50 CM4 |

|

Maximum distance between tailstock tips [mm]

|

680 |

|

Maximum diameter of installable tool on the tailstocks [mm]

|

275 |

|

Installed power

|

|

|

On board machine power [kW]

|

4 |

|

Dimensions

|

|

|

Width x Depth x Height [mm]

|

1650x1250x1730 |

|

Overall weight [kg]

|

1100 circa |