Request

The Dutch customer Machinefabriek Krimpen, a company specialized in gear wheels, was looking for a machine capable of producing particularly long keyways as well as internal and external gears with manufacturing precision.

Solution

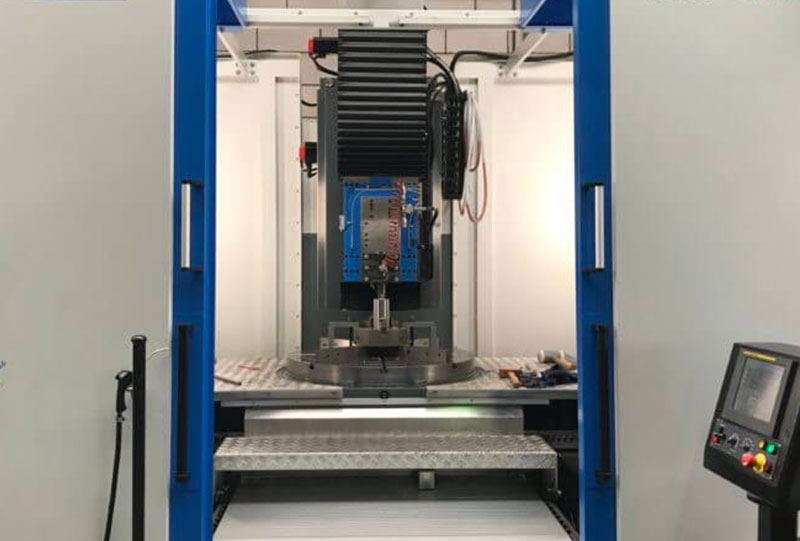

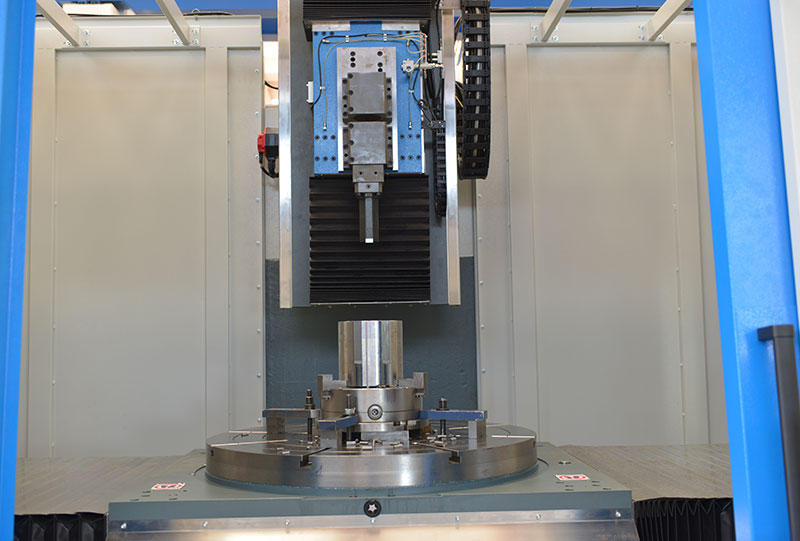

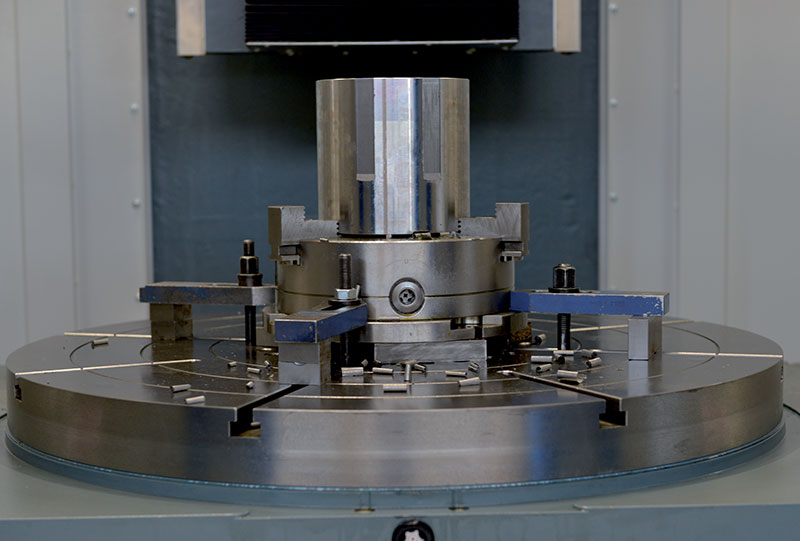

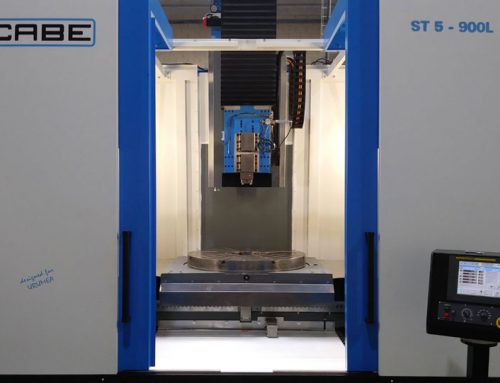

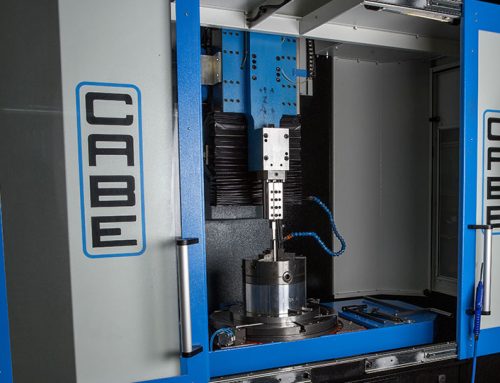

The Cabe team has developed a machine with 5 controlled axes, model ST5-610, extremely efficient, able to make internal and external keyways with a maximum length of 610mm. The software, developed ad hoc for the machine, allows, by operating the 5th axis, to change the distance between the table and the underhead quickly and effortlessly, allowing rapid processing changes. The interface is easy to use and allows the programming of many types of processing.

Result

With the CABE ST5 CNC machine, Krimpen is now able to carry out work previously delegated to external suppliers, and therefore, to satisfy new requests from the customers. The great flexibility of the machine makes it possible to alternate the production of very different pieces and the brushless motor with head adjustment control allows the placement of the highest pieces with enormous time savings.

“The adjustable ramholder makes it possible to have a steady cut in each height. The free programmable controller will let you cut each shape and control the movement of the machine. Because of the wide deployable functionality, we can produce almost any product within the boundaries of the machine.“

Collin van Diem,

Machinefabriek Krimpen