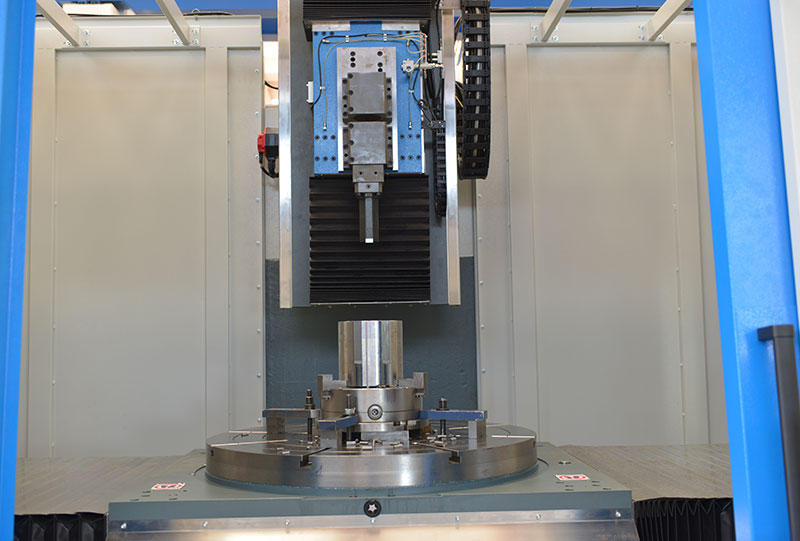

Cabe launches the new slotting machine ST5 with 5 controlled axes. As a result of the continuous research, the ST5 CNC allows articulated machining and ground-breaking performances.The 5th axis allows the automatic management of the distance between the underhead and the swivel table.

The machine is characterized by a modern design, innovative technologies and by Fanuc control panel and motors. Available in diverse models with different stroke of the tool (starting from 610mm), the ST5 CNC is ideal for the machining of particular big pieces.

The movement of the head, controlled by Fanuc brushless motors, is done with the control, that keeps in memory the start position and repeats it automatically if needed.

The accessibility to the machine is guaranteed by a walkable roller shutter: it is always possible to have a close-up control of the piece and the tool for set-up of the machine.

The fifth axis, introduced expressly for the models with elevated stroke of the tools, consents to easily modify the distance between the table and the underhead allowing a fast change of the machining.

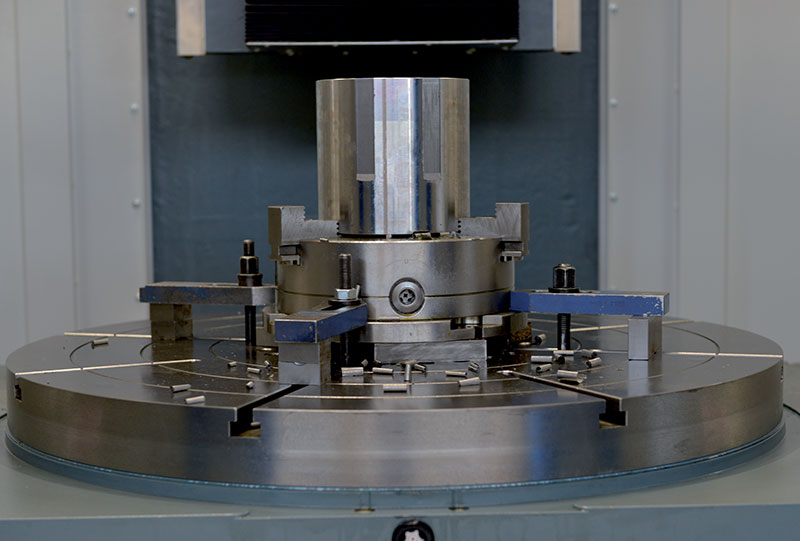

As on the entire range of Cabe CNC machines, the traditional rod-crank system for moving the tool has been replaced by a servo-controlled linear axis that guarantees a quick set-up of the machine, a constant cutting speed and the possibility to perform unique processing such as: Blind slots without discharge hole, Helical slots and Conical with the interpolation of 2 axes.

The Fanuc software is developed to guide the user in the configuration of the machine. Thanks to the personalized pages the ISO programs are generated with parameters, extremely useful for the operator, that makes it possible to avoid long training periods, also in case of very complex processing.

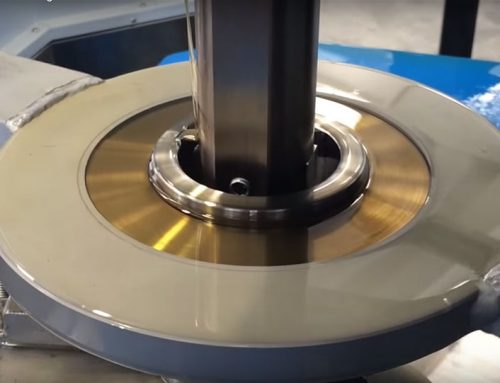

The new tool holder with high repeatability is installed on the machine. Thanks to this innovative tool holder the tools are always at the centre of the hole. Combined with the tool holder, the “VCT” system, virtual tool change, allows two processes with different tools without having to stop the machine to make the change.